- LocationPhiladelphia, PA

- Date2014

- ServicesMechanical Construction // Plumbing

Use of Existing Utilities Saves Time and Money for St. Christopher’s Hospital for Children

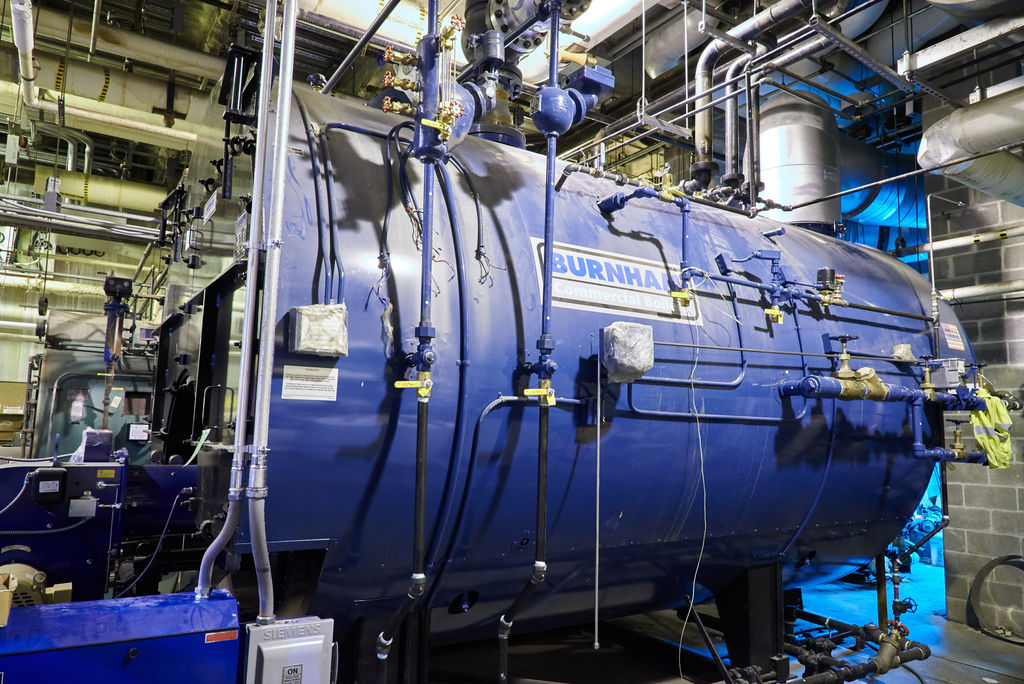

St. Christopher’s Hospital for Children, a renowned pediatric care provider since 1875, recently expanded with a $110 million, 135,000-square-foot Critical Care Tower featuring 39 neonatal care beds, an upgraded dental unit, a larger therapy gym, and enhanced amenities. Torcon Construction selected Herman Goldner Co., Inc. to handle the mechanical and plumbing work, led by Senior Project Manager Andrew Cipollono. Goldner upgraded the existing utility plant—installing new chillers, boilers, and medical gas equipment—to serve both the new tower and the existing hospital without service interruptions. Temporary systems ensured continuous operation, with meticulous planning to minimize impact on the occupied facility.

Download ArticleSee Us In Action

On behalf of CBRE Property Management, congratulations to Andrew Cipollono and the entire Herman Goldner Co., Inc. and Erickson team for their flawless and safe execution of the cooling tower replacement at 2000 Market Street in Philadelphia this morning.”