Delivering Over a Century of Exceptional Service

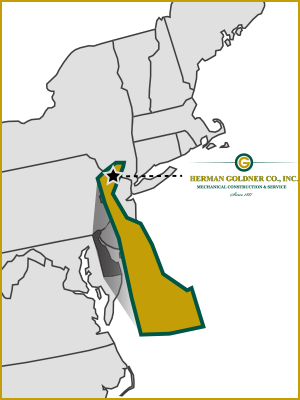

Since 1887, Herman Goldner Co., Inc. has been delivering quality craftsmanship and exceptional service to the Greater Delaware Valley area. As a full-service mechanical provider, our experienced team offers cost-effective, high-quality solutions tailored to your needs.

These men laid the foundation on which we continue to build. Their vision, values, and unwavering commitment to integrity live on in every project.

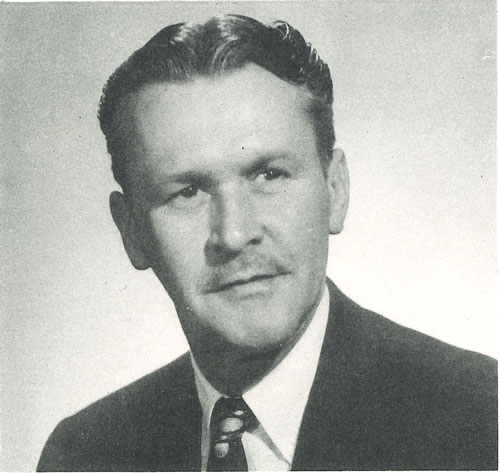

Herman J. Goldner

1887 - 1929 (President)

Roy J. Goldner

1929 - 1943 (President)

Herman W. Goldner

1943 - 1959 (President)

Dave Super

1959 - 1964 (President)

Herman E. Goldner

1964 - 1995 (President)

1995 - 2000 (CEO)

Gerard C. Goldner

1995 - 2000 (President)

2000 - 2008 (CEO)

Steve J. Williams

2000 - 2025 (President)

Herman W. Goldner

2008 - Present (CEO)

Our Stories &

Our History

New Leadership Team

CAD Renovations

The CAD Department was expanded and renovated to add more workstations to the department. A software change from AutoCAD to Revit was introduced to allow for more complex designs and advanced fabrication along with added collaboration capabilities.

Facility Expansion

In 2021, a 3,000-square-foot clean room was established for stainless steel fabrication. That same year, a 10,000-square-foot modularization shop was added to support modular rack, HVAC, and process skid fabrication.

New Additions

A new entity, Herman Goldner Company NJ, Inc., was established.

Improvements

Improvements were made to the Weld Fabrication Shop, including the addition of an indoor 5,600-square-foot pipe fabrication shop. This facility features a state-of-the-art Lincoln Electric CNC piping cutting system.

Celebrating 125 years

Herman Goldner Co., Inc. celebrates their 125th Anniversary!

Safety Committee Accreditation

In 2009, Herman Goldner Co.’s Safety Committee becomes certified by the state of Pennsylvania for establishing and maintaining an effective workplace safety environment.

A legacy continued

In June 2008, Gerard Goldner retired and Herman W. Goldner (fourth generation) assumed the position of CEO.

Safety Committee

In 2001, Herman Goldner established a Safety Committee to engage both management and field staff in promoting safety, preventing injuries, and maintaining a healthy work environment.

Exciting changes

In July of 2000, Gerard C. Goldner assumed the role of CEO and Stephen J. Williams, a former Divisions Manager and Vice President, was appointed President/COO of the corporation.

New leadership & expansion

Herman E. Goldner was appointed CEO, and Gerard C. Goldner became President. That same year, a 10,000-square-foot Technical Center was built on the Brewster site to house Construction Planning, CAD, Mechanical Services, and Building Automation.

CAD Drafting

In 1989, Herman Goldner Co. created a Preplanning Department to leverage AutoCAD to help with design, coordination, fabrication and delivery of mechanical, plumbing and process systems.

Celebrating 100 years

The company celebrated its 100th anniversary in May 1987. Its success was rooted in the enduring values of its founders and the loyalty and dedication of employees and customers.

Service Division

In 1985, Herman Goldner Co., started a service division to provide reliable and cost-effective mechanical services, ensuring the safety and functionality of systems while building trust and relationships with our customers.

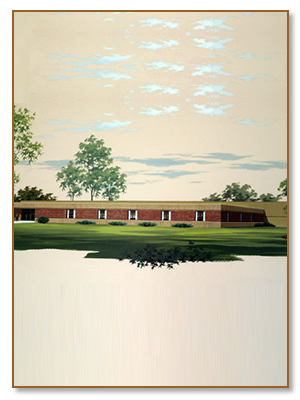

New headquarters

In 1979, a new facility was opened combining all operations at 7777 Brewster Avenue, Philadelphia, PA on 12 acres of ground and comprising over 100,000 square feet of office, warehouse and pipe storage space.

Expansion

The opening of a branch operation in New Castle, Delaware in November, 1970, to serve the Petrochemical and Refinery industries.

Continued growth

Herman E. Goldner, the founder’s grandson, succeeded Davis R. Super as President. Continued expansion led to a move into a larger facility on Hunting Park Avenue in November 1964.

New beginnings

After the passing of Herman W. Goldner, longtime employee Davis R. Super, who had joined the company in 1932, was elected President. He led the firm until his retirement in 1964.

Tough times

Following the death of founder Herman J. Goldner, his eldest son Roy J. Goldner assumed leadership. He successfully guided the company through the Great Depression until his sudden death in 1943, after which the youngest son, Herman W. Goldner, took the helm.

Moving on up

The Company later moved from a Hancock Street basement to larger quarters at 425 W. Lehigh Avenue, and in 1919 was incorporated under the laws of the State of Pennsylvania.

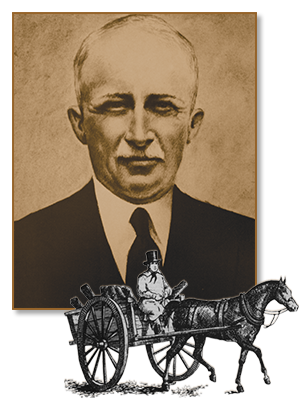

The beginning

Herman J. Goldner started his business in a Philadelphia basement, delivering plumbing supplies by wheelbarrow and horse-drawn cart. Built on the values of integrity, service, and quality, his approach became a recognized hallmark and a lasting legacy.

Jump to 1887

Jump to 1887

Meet Our Leadership Team

Executives

Managers

Jenn Grasso

Controller

Safety at the Forefront

At Herman Goldner Co., Inc., safety is a top priority. Our comprehensive Safety Program includes four key elements: Management Commitment, Hazard Identification and Correction, Education and Training, and Employee Involvement. Together, these components create a safe and effective work environment. To support these four elements, our Safety Program includes:

Active Safety

Committee

Monthly safety meetings, led by executive management and attended by staff and field representatives, with included participation from the CEO. Topics covered include incidents, hazards, employee safety contributions, and training needs.

Safety Observation

Sighting (SOS) Program

The Herman Goldner Co., Inc. SOS Program enables personnel to report safety issues and notable field conditions to both site and company management for quick corrective action.

Weekly Safety

Training

Weekly safety toolbox talks are conducted at each construction site with materials specific to mechanical trades. For employees like Service Technicians who are not at fixed sites, a mandatory web-based safety training program is used. Attendance is documented and reviewed periodically.

Safety Orientation

Every new employee receives an orientation on company policies and a Safety Handbook from the Mechanical Contractors' Association, covering over 50 topics and 40 graphics specific to mechanical trades. Drivers also get a manual on company vehicle regulations.

-

Specialized Training

We provide specialized safety training, including Lockout Tagout, First Aid, OSHA programs, and more, to ensure all employees are equipped to identify and address hazards on the job.

-

Personal Protective Equipment

Safety glasses and hard hats are mandatory for all Herman Goldner Co., Inc. employees. Managers and the Company Owner model proper PPE use, and infractions are addressed promptly. Foremen and project managers can purchase additional safety gear as needed.

-

Safety Equipment

We supply essential safety equipment on job sites, including fiberglass ladders, fall protection gear, OSHA-compliant scaffolds, confined space meters, welding machines, arc flash protection, and electrical meters for Service Technicians.

-

Written Program

We develop and periodically review safety and health policies with loss control professionals and management. Site-specific plans are created as needed for tasks like lockout, crane lifts, and fall protection.

-

Safety Award Program

The program tracks field incidents and rewards the team semi-annually if targets are met, with an extra year-end drawing if annual goals are achieved. Clients require an incident level below 4.0.

-

Site Inspections

We conduct daily site inspections by foremen and periodic comprehensive checks by a safety engineer, covering site conditions, work practices, and training. Reports are reviewed monthly to ensure ongoing safety.

-

Job Safety Planning

Safety and health are addressed in construction focus meetings, project turnovers, and bid proposals to manage hazards. Site-specific safety plans are developed as needed for operations like crane lifts, fall protection, confined space entry, and hot work.

-

Analysis of Safety Performance

We analyze incidents, injuries, and SOS reports monthly and annually, with reviews by management and the safety committee. This process identifies concerns and recognizes employee performance. For instance, the mandatory use of safety glasses on lanyards resulted from this analysis.

-

Related Safety Articles

Merck 2013 West Point Contractor Safety Award

Read ArticleMerck 2014 West Point Contractor Safety Award

Read Article

Philanthropy

At Herman Goldner Co., Inc., we believe in not only providing quality services but also giving back to our community. Our core values of integrity, service, and quality are supported by the generosity of local organizations. Here is a partial list of those we’ve recently supported.

Community Involvement

Army-Navy Cup VI

Soccer Game

Philadelphia, PA

Since 2012, Herman Goldner Co., Inc. has sponsored the Army-Navy Cup, held annually at Talen Energy Stadium, home of the Philadelphia Union. We are proud to support this memorable collegiate soccer event.

Concept School

Golf Outing

Philadelphia, PA

23rd Annual Tournament Fundraiser for The Concept School.

"I am thrilled to announce that this was our 23rd annual Tournament Fundraiser for The Concept School. We could not have reached this milestone without your generous support. Your time and contributions have made a meaningful impact on many children’s lives, and I am deeply grateful.

The Concept School, established 45 years ago, supports students in overcoming learning obstacles. Its dedicated staff provides personalized attention to help each child realize their potential and find their place in society.

The proceeds from this tournament directly support The Concept School’s goals. Thank you for joining us on the greens and for sponsoring this important community event.”

With sincere gratitude,

Herman Goldner